Introduction to Sheet Metal Die Design: Processes, Principles, and Applications

Sheet metal die design is the backbone of mass manufacturing for countless industries—automotive, aerospace, appliances, and beyond. At its core, it involves the design of specialized tooling (dies) used to cut, bend, and form sheet metal into precise shapes and functional components. This article serves as a comprehensive introduction to the world of sheet metal die design, offering a foundation for engineers, designers, and manufacturers seeking to understand or improve their metal forming operations.

What Is Sheet Metal Die Design?

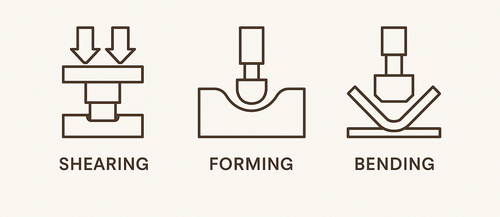

Sheet metal die design refers to the engineering and creation of tools used in mechanical presses to transform flat sheet metal into desired shapes through operations like:

Shearing – Cutting material along straight or complex lines.

Forming – Reshaping the metal without cutting, to achieve curves or contours.

Bending – Deforming the metal along a straight axis to create angles or folds.

These operations are performed using custom dies—precision tools made from hardened materials—mounted into presses to ensure repeatable, efficient, and high-volume production.

Why Is Die Design Important?

Poor die design can lead to:

Material waste

Tool wear and breakage

Poor dimensional accuracy

Increased setup and maintenance time

Conversely, good die design enables:

Consistent part quality

Increased tool life

Lower production costs

Faster time-to-market

Key Categories of Sheet Metal Operations

1. Shearing

Shearing involves cutting the metal without forming chips. It's done using punch-and-die setups, and it's often the first step in blanking or trimming.

Typical Uses: Cutting blanks, creating slots, removing scrap.

Important Parameters: Shear force, die clearance, punch geometry.

2. Forming

Forming reshapes the metal plastically without cutting or removing material.

Processes: Drawing, stretching, embossing, flanging.

Formability depends on ductility, grain direction, and lubrication.

3. Bending

Bending is used to create angles or curves in flat sheet material. The design must account for:

Bend allowance: Added length in the flat pattern to compensate for stretching during bending.

Springback: The tendency of the material to partially return to its original shape.

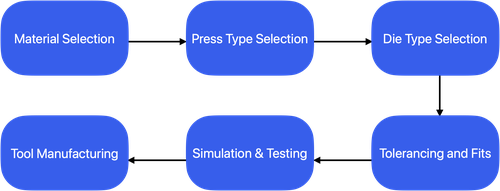

Sheet Metal Die Design Workflow (Overview)

Material Selection: Based on ductility, thickness, and end-use properties.

Press Type Selection: Hydraulic, pneumatic, eccentric, etc.

Die Type Selection: Shear die, forming die, compound die, progressive die.

Tolerancing and Fits: Precision fit between punch and die.

Simulation & Testing: Virtual tryouts to predict performance before production.

Tool Manufacturing: Final machining, heat treatment, and assembly.

The Role of the Die Designer

A die designer balances engineering theory with practical production needs. Their job includes:

Ensuring manufacturability (DFM)

Maximizing tool life

Reducing production costs

Designing for ease of maintenance and changeover

Final Thoughts

Sheet metal die design is not just about creating tooling—it's about building the foundation of efficient, high-quality manufacturing. This introduction sets the stage for deeper exploration into machines, material choices, simulations, and maintenance strategies—all of which will be covered in upcoming articles.