Understanding Press Machines in Sheet Metal Operations

Press machines are at the heart of every sheet metal operation, providing the force and precision required to cut, bend, and form metal parts. Understanding the types of presses and their operational principles is essential for die designers, production engineers, and plant managers. This article explains the different categories of press machines used in the sheet metal industry, comparing their mechanisms, applications, and advantages.

Why Press Machines Matter

In sheet metal fabrication, the press machine is responsible for:

Delivering the force needed to shape or cut metal

Defining the production rate and precision

Determining the type of die and tooling required

Choosing the right press enhances productivity, reduces maintenance, and ensures consistent part quality.

Types of Press Machines

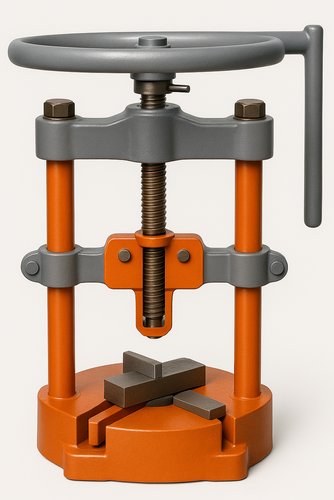

1. Manual and Friction Presses

Manual Handle Press:

Operated by physical effort

Ideal for light-duty tasks

Offers high control but is slow and operator-dependent

Friction Press:

Utilizes flywheels and friction for greater force

Suitable for forging and coining operations

Provides more uniform results than manual presses

2. Hydraulic and Pneumatic Presses

Hydraulic Press:

Uses hydraulic fluid under pressure

Operates at 70–700 bar (for heavy-duty models)

Known for high force and consistent performance

Ideal for deep drawing and forming applications

Pneumatic Press:

Uses compressed air (typically 5.5–10 bar)

Faster and more energy-efficient

Suited for lighter tasks and medium production volumes

Force Calculation:

F = P . A

Where:

P: Pressure (bar),

A: Area of the cylinder (m^2)

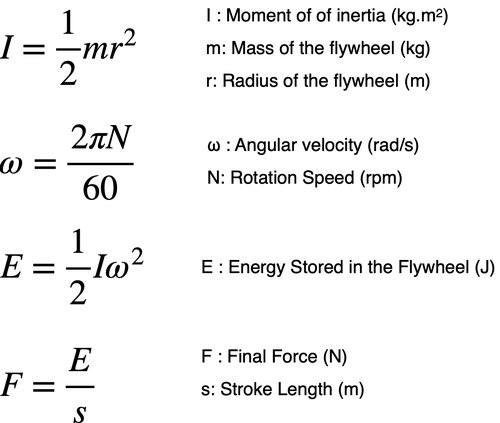

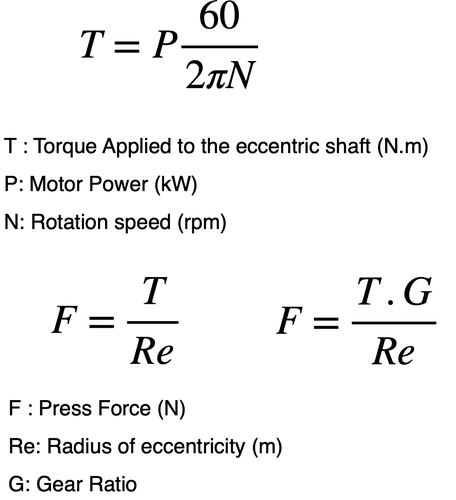

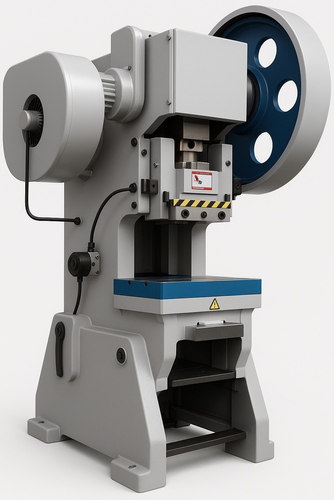

3. Eccentric Press

How It Works:

Converts rotary motor motion into linear ram motion via an eccentric shaft

Stroke length is determined by the shaft's eccentricity

Frame Types:

C-Frame Single Crank

H-Frame Single/Double Crank

Applications:

Punching, stamping, and shearing operations

High-speed, repetitive production tasks

4. Press Brake

Function:

Designed to bend sheet metal by pressing it between a punch and die

Key Characteristics:

Uses hydraulic systems for controlled movement

Forms angular bends or complex profiles

Offers high precision in bending operations

Selecting the Right Press Machine

Press Type | Best For | Force Range | Speed | Cost |

|---|---|---|---|---|

| Manual Press | Simple, low-volume tasks | Low | Very slow | Low |

| Friction Press | Forging, coining | Medium–High | Moderate | Medium |

| Hydraulic Press | Deep drawing, high force | High (up to 700 bar) | Slow–Medium | High |

| Pneumatic Press | Light forming, fast operation | Low–Medium | Fast | Medium |

| Eccentric Press | Punching, stamping | Medium–High | Very fast | Medium |

| Press Brake | Precision bending | Variable | Moderate | High |

Final Thoughts

Selecting the proper press machine is a crucial decision in die design and sheet metal manufacturing. It determines everything from tooling to energy consumption and production capacity. Understanding the fundamental differences between manual, hydraulic, pneumatic, eccentric, and press brake systems is essential for making the best choice for your operation.